TUNE THE BOWLING BALL TO MATCH YOUR STYLE

WHY SURFACE MATTERS

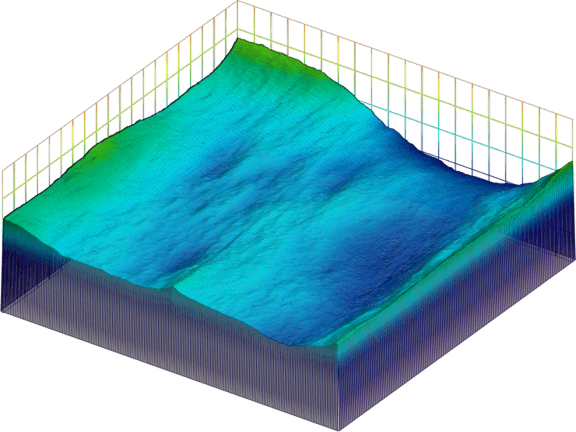

Imagine your bowling ball is like a car tire — how it grips the road (or in this case, the lane) depends on the surface.

When you tune the surface of a bowling ball, you’re adjusting how early or late it grips the lane. That helps you control:

– How much the ball hooks

– When it starts hooking

– How it reacts to oil

If the surface doesn’t match your style or the lane conditions, the ball might:

– Hook too early and lose power

– Slide too far and miss the pocket

– React inconsistently

Here’s a Simple Breakdown:

| Your Style | What That Means | What You Might Need |

|---|---|---|

| High ball speed | Ball may skid too far | Rougher surface to help grip earlier |

| Low revs (less spin) | Harder to create hook | Rougher surface to add traction |

| High revs | Ball can hook too much | Smoother or polished surface to delay the hook |

| Play down and in | Direct line to pocket | Smoother surface to avoid overreaction |

| Play hook | Big swing to the pocket | Smoother or polished surface for backend motion |

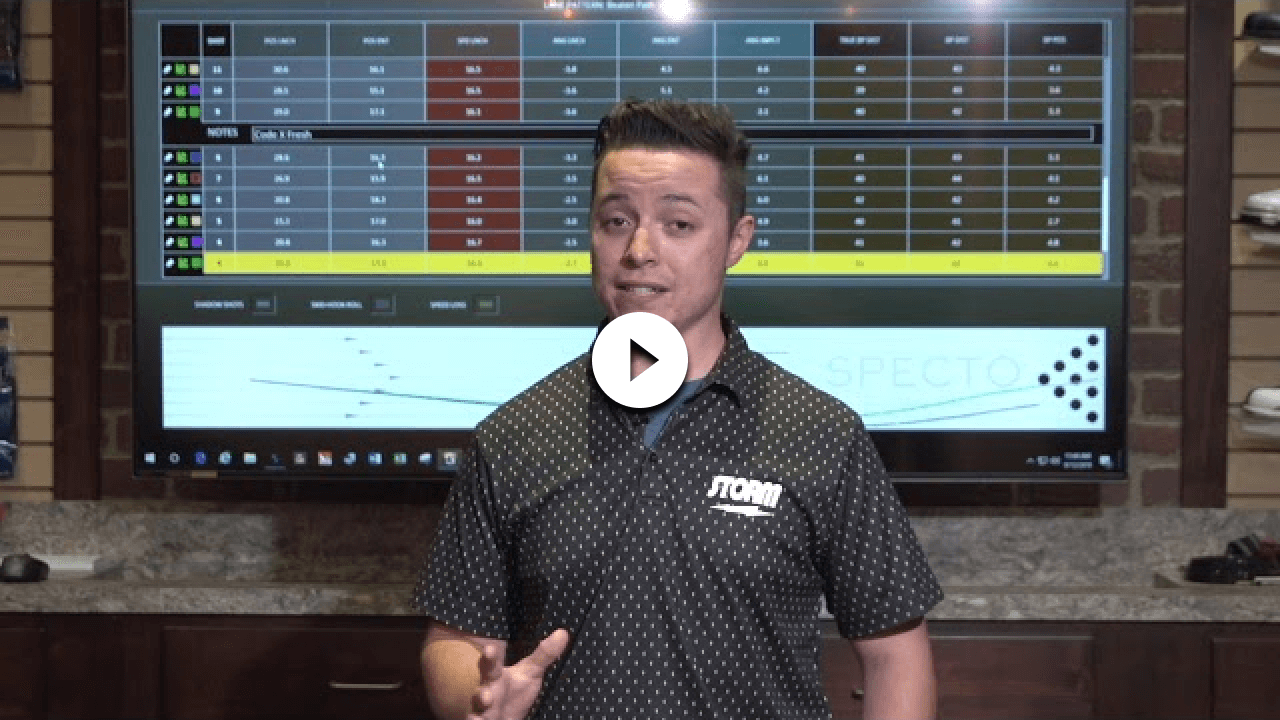

HOW TO CHANGE YOUR BALL SURFACE

5:51

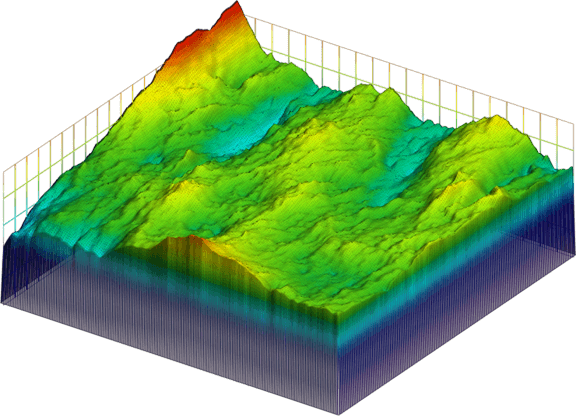

500 GRIT

Great starting grit for building surface. It provides strong overall

traction

and is

commonly used as a first step in sanding progression.

Use cases:

– Creating surface underneath polish

– Medium-heavy oil conditions

– Players who need predictable midlane read

– Surface prep before 1000/2000/4000 polish finishes

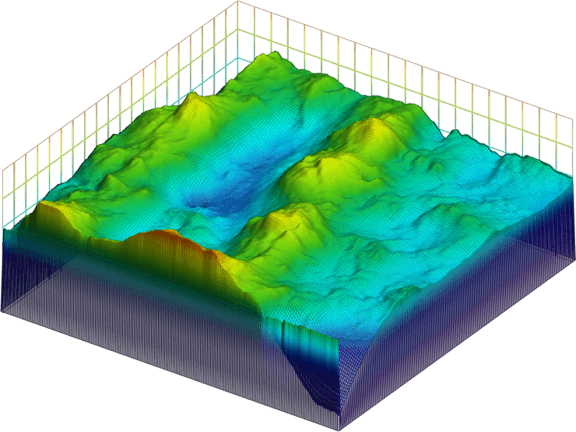

1000 GRIT

Balances traction and length well. It’s a versatile surface that still

offers

some

bite without being too early.

Use cases:

– League house shots with moderate oil

– Players who want midlane control and some backend motion

– Surface tuning without killing backend

– Balls that are too sharp at box finish

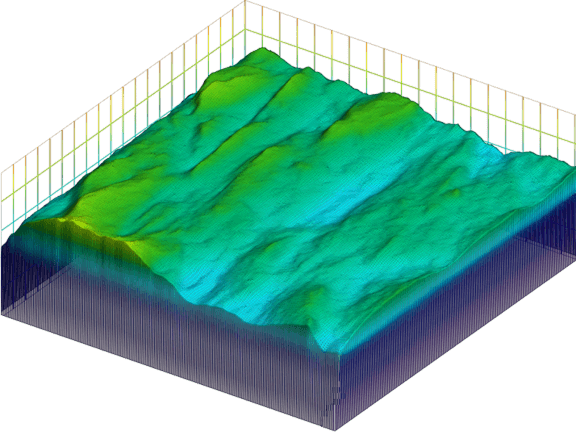

2000 GRIT

One of the most popular and balanced surfaces. Provides moderate length

with

a

smooth transition and strong arc.

Use cases:

– Medium oil conditions

– Tournament prep for fresh patterns

– Smoothing backend overreaction

– Rev-dominant players looking to shape motion more predictably

3000 GRIT

Creates length with a smooth, readable backend. It helps balls retain

energy

and

arc

more smoothly compared to higher friction grits.

Use cases:

– Medium to dry conditions

– Smoother backend motion

– Players who want control without early hook

– Slightly dulling a polished ball without killing shape

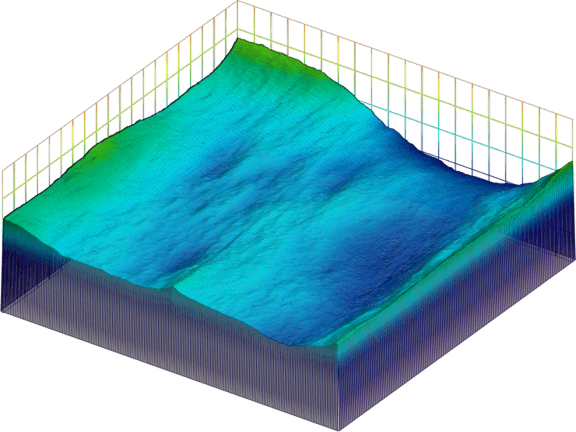

4000 GRIT

Delivers length and strong backend motion. Often used to lightly tune

reactive

balls

for clean skid-flip shapes without full polish.

Use cases:

– Medium to light oil

– Getting balls clean through the front with strong backend

– Players who want more pop downlane without full shine

– Final surface before applying polish

WHEN TO RESURFACE YOUR BOWLING BALL

5:51

scroll and select to switch products

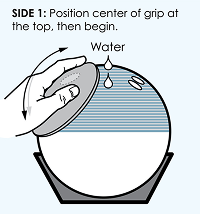

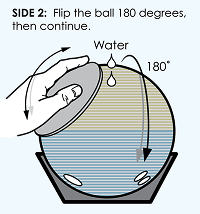

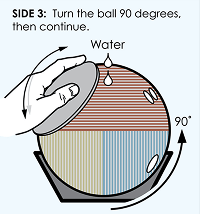

500 GRIT FINISH

1. 360 grit - Firm pressure for 30 sec.

2. 500 grit - Light pressure for 5 sec.

1000 GRIT FINISH

1. 500 grit - Firm pressure for 30 sec.

2. 1000 grit - Light pressure for 5 sec.

2000 GRIT FINISH

1. 500 grit - Firm pressure for 30 sec.

2. 2000 grit - Light pressure for 10 sec.

3000 GRIT FINISH

1. 500 grit - Firm pressure for 30 sec.

2. 3000 grit - Light pressure for 10 sec.

4000 GRIT FINISH

1. 500 grit - Firm pressure for 30 sec.

2. 2000 grit - Medium pressure for 10 sec.

3. 4000 grit - Light pressure for 5 sec.

POWER EDGE

1. 500 grit - Firm pressure for 30 sec.

2. 1000 grit - Light pressure for 10 sec.

3. Quarter size amount of Power Edge - High pressure for 15 sec.

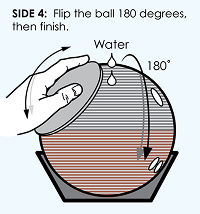

4. Wipe excess polish as needed - Use water as needed.

.jpeg)